Greetings, fellow enthusiasts of metallurgy and industrial innovation. I am thrilled to dive into the world of Silicon Metal, a substance that has been pivotal in shaping modern industries and pushing the boundaries of what's possible. As the leader of chenggang metal, a frontrunner in metallurgical solutions, I am honored to introduce you to the remarkable world of silicon metal.

What is Silicon Metal?

Silicon metal, often referred to as "Si-Metal," is a versatile and indispensable material with a wide range of applications across various industries. At its core, silicon metal is a refined product derived from silicon-rich ores, and it is primarily composed of silicon with small traces of other elements. Its purity, typically exceeding 98%, makes it a valuable commodity in the metallurgical world.

|

|

|

Si-Metal is renowned for its remarkable properties, including high thermal conductivity, excellent electrical conductivity, and corrosion resistance. These attributes have made it a cornerstone in numerous industrial processes, from electronics to construction, and from automotive engineering to solar power generation.

| Grade | Chemical composition(%) | |||

| Si | Fe | Al | Ca | |

| Min | Max | |||

| 553# | 98.5 | 0.5 | 0.5 | 0.3 |

| 441# | 99.0 | 0.4 | 0.4 | 0.1 |

| 421# | 99.0 | 0.4 | 0.2 | 0.1 |

| 3303# | 99.0 | 0.3 | 0.3 | 0.03 |

| 2202# | 99.0 | 0.2 | 0.2 | 0.02 |

| 1101# | 99.0 | 0.1 | 0.1 | 0.01 |

How Does Silicon Metal Benefit Industries?

- Electronics and Semiconductors Silicon metal is the bedrock of the electronics industry. It is the fundamental material used in the manufacturing of semiconductors and microchips. The remarkable electronic properties of silicon, such as its ability to conduct electricity while serving as an insulator, are harnessed to create the intricate circuits that power our modern devices.

- Solar Energy In the quest for clean and renewable energy, silicon metal takes center stage. It is a key component in photovoltaic cells used to capture sunlight and convert it into electricity. The solar panels that adorn rooftops and solar farms worldwide rely on high-purity silicon metal to harness the power of the sun.

- Metallurgical Alloys Silicon metal plays a crucial role in the production of various metallurgical alloys, including ferrosilicon, silicomanganese, and silicon carbide. These alloys find applications in the steel and foundry industries, enhancing the quality and performance of metal products.

- Chemical Industry In the chemical sector, silicon metal is employed in the synthesis of silicone compounds, which are used in a wide range of applications, from sealants and adhesives to medical implants. Its versatility in this realm makes it an essential building block for countless chemical innovations.

- Aerospace and Automotive Aerospace and automotive industries rely on silicon metal for its lightweight and high-strength properties. It is used in the manufacturing of specialized alloys and components, contributing to the safety and efficiency of modern vehicles and aircraft.

Silicon Metal: The Unsung Hero of Modern Technology

As we traverse the landscape of modern technology, silicon metal remains an unsung hero. It's the silent conductor powering our smartphones, the foundation of renewable energy, and the secret ingredient in countless products that enhance our lives.

The remarkable conductivity of silicon metal is what allows us to send information at the speed of light through fiber optic cables, power electric vehicles, and store vast amounts of data in minuscule devices. Its ability to withstand extreme temperatures and harsh environmental conditions makes it an ideal choice for applications that demand reliability and longevity.

The Silicon Metal Production Process

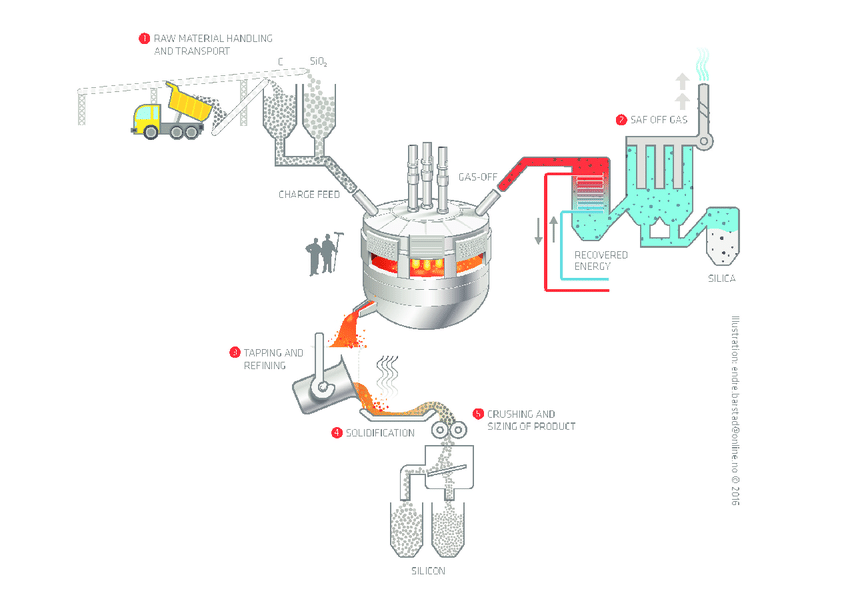

The journey of silicon metal from its raw form to the refined product we know today is a fascinating one. Let's take a glimpse into the production process:

- Raw Material Extraction The journey begins with the extraction of silicon-rich ores, often quartz or sand. These ores are carefully selected for their purity and suitability for silicon metal production.

- Smelting Process The selected ores are subjected to a high-temperature smelting process, typically in an electric arc furnace. This process involves the reduction of silicon dioxide (SiO2) to obtain pure silicon metal. Carbon electrodes are used to generate the necessary heat and reduce the silicon dioxide to silicon metal.

- Refining and Purification The obtained silicon metal undergoes further refining and purification processes to achieve the desired purity levels. Various methods such as fractional distillation and chemical treatments are employed to remove impurities and obtain high-purity silicon metal.

- Final Product The result is a product with exceptional purity and uniformity, ready to be shipped to industries worldwide. Its remarkable properties make it an invaluable resource in various sectors, contributing to technological advancements and sustainable practices.

Innovations in Silicon Metal Production

The production of silicon metal has come a long way, with innovations continuously improving efficiency and sustainability. One notable advancement is the adoption of cleaner energy sources in the smelting process. Many producers are transitioning to renewable energy, such as hydropower and solar, to reduce carbon emissions associated with silicon metal production. Furthermore, research is ongoing to explore alternative raw materials and more environmentally friendly production methods. These efforts aim to make silicon metal production even more sustainable and reduce its environmental footprint.

Silicon Metal in the Solar Revolution

The global shift towards clean and sustainable energy sources has propelled the demand for silicon metal to new heights. Solar energy, in particular, has experienced exponential growth, and silicon metal is at the heart of this revolution.

The efficiency and cost-effectiveness of photovoltaic cells, which rely on silicon metal, have improved significantly over the years. This has made solar power more accessible and affordable for communities and businesses worldwide, paving the way for a greener and more sustainable future.

The Future of Silicon Metal

As we stand on the cusp of a new era filled with technological breakthroughs and environmental challenges, silicon metal remains a beacon of innovation and sustainability. Its versatile properties, from conductivity to durability, continue to drive advancements in various industries.

In the coming years, we can expect to witness even more exciting developments in silicon metal production and applications. As a leader in metallurgical solutions, CG is committed to being at the forefront of these innovations, providing you with the highest quality silicon metal products that meet the evolving needs of your industry.

Join Us in Shaping the Future

In conclusion, silicon metal is not merely a material; it's a catalyst for progress and sustainability. Its role in electronics, renewable energy, metallurgy, and countless other sectors is undeniable. As the leader of CG, I invite you to explore the vast possibilities that silicon metal offers for your industry. If you have any questions, require further information, or wish to discuss how silicon metal can elevate your projects and products, please reach out to us. We are here to provide expert guidance and supply you with premium-quality silicon metal to propel your business forward.

Contact Us Today!

We welcome inquiries in English, Español (Spanish), Русский язык (Russian), Français (French), and العربية (Arabic).

Our professional team will reply to you within one business day. Please feel FREE to contact us!

Your privacy is important to us,we are committed to marking sure your privacy is

confidential.